PUMPA - SMART LEARNING

எங்கள் ஆசிரியர்களுடன் 1-ஆன்-1 ஆலோசனை நேரத்தைப் பெறுங்கள். டாப்பர் ஆவதற்கு நாங்கள் பயிற்சி அளிப்போம்

Book Free DemoFibre into wool:

Wool that is used to knit sweaters or weave shawls is the result of a lengthy process that includes the following steps:

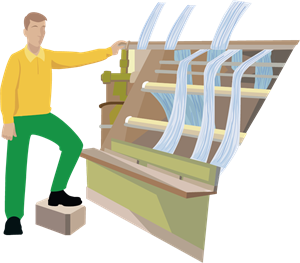

Step I: The sheep's fleece and a thin layer of skin are removed from its body. This method is called shearing.

Shearing of hair

Machines parallel to those used by barbers are used to shave off hair. Usually, hair is removed during hot weather. This enables sheep to survive without their protecting coat of hair. The hair gives woollen fibres.

Woollen fibres are then processed to get woollen yarn. Shearing does not hurt the sheep, just as it does not hurt when you get a haircut or your father shaves his beard. Do you know why? The outer layer of the skin is dead. Also, sheep's hair grows again, just as your hair does.

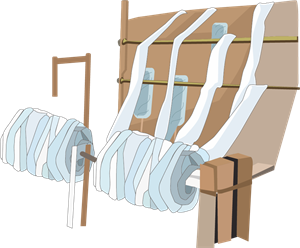

Step II: The sheared skin with hair is thoroughly cleaned or washed in tanks to remove grease, dust and dirt. This is called scouring. In recent days, the scouring has been done by machines.

Scouring in tanks

Scouring by machines

Step III: After scouring, sorting is done. The hairy skin is sent to a factory (industry), where the hair of various textures is divided or sorted.

Step IV: The tiny fluffy fibres, named burrs, are selected from the hair. These are the exact burrs which occasionally occur on your sweaters. The fibres are cleaned again and dried. This is how the wool that is drawn into fibre is produced.

Step V: The fibres can be coloured in different colours, as the natural fleece of sheep and goats is black, brown or white.

Step VI: Straighten, comb, and roll the fibres into yarn. The longer fibres are spun and woven into woollen cloth, while the shorter fibres are used to make sweaters.

Rolling into yarn

The processing of fibre into wool can be expressed as follows:

Shearing → Scouring → Sorting → Cleaning of burrs → Dyeing → Rolling