PDF chapter test TRY NOW

There are four types of ore separation based on the nature of the ore.

- Hydraulic (Gravity Separation) method.

- Magnetic separation method.

- Froth floatation.

- Chemical method or Leaching.

The different types of ores of metals are given in the below table:

Oxide Ores | Carbonate Ores | Halide Ores | Sulphide Ores |

| Bauxite (Al_2O_3.2H_2O) | Marble (CaCO_3) | Cryolite (Na_3AlF_6) | Galena (PbS) |

| Cuprite (Cu_2O) | Magnesite (MgCO_3) | Fluorspar (CaF_2) | Iron pyrite (FeS_2) |

| Haematite (Fe_2O_3) | Siderite (FeCO_3) | Rocksalt (NaCl) | Zinc blende (ZnS) |

The concentration of the crushed ore is done mainly by the following methods:

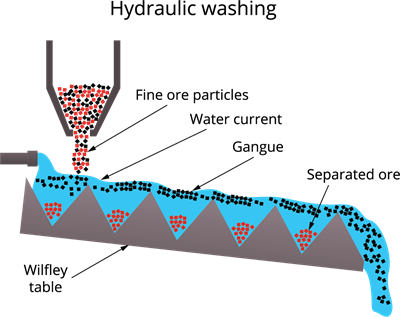

1. Hydraulic (Gravity Separation) method:

Principle:

The difference in the density or specific gravity of the ore and gangue is the main principle behind this method.

Oxide ores are purified by this method.

Example:

Haematite Fe_2O_3 the iron ore.

Important!

Note: Hydraulic method is used when the ore is heavier than the impurity.

Method:

Hydraulic washing

The ore is poured onto a sloping, vibrating corrugated table with grooves, then washed down with a stream of water.

Industrial ore washing process

The denser ore particles settle in the grooves, while the lighter gangue particles are washed away by water.

The denser ore particles settle in the grooves, while the lighter gangue particles are washed away by water.