PDF chapter test TRY NOW

Important reminders:

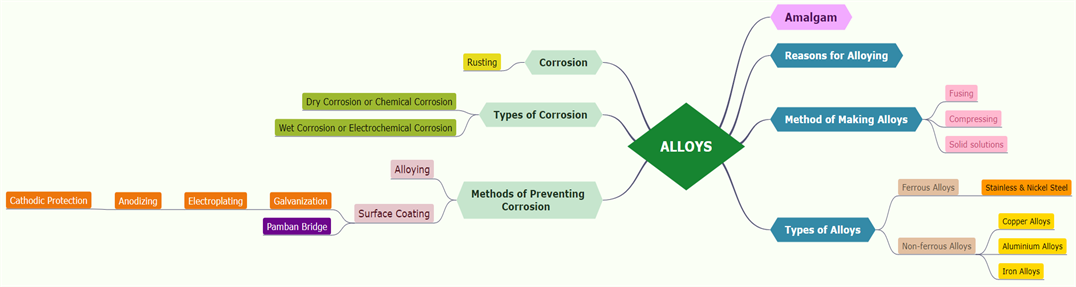

An alloy is a homogeneous mixture of two or more metals or of one or more metals with certain non-metallic elements.

An amalgam is a mixture of mercury and another metal. These alloys are formed by metallic bonding, which uses the electrostatic force of attraction between electrons and positively charged metal ions.

Reasons for alloying:

To change appearance and colour, chemical activity, to reduce the melting point, to improve hardness and tensile strength, to improve resistance to electricity.

Method of making alloys:

1. The metals are fused together.

2. Finely divided metals are compressed.

Types of alloys:

Ferrous alloys and Non-ferrous alloys based on iron component.

Ferrous alloys are stainless and nickel steel.

Non-ferrous alloys are aluminium and copper alloys.

Corrosion is a gradual destruction of metals by chemical or electrochemical reactions to the environment. It is a natural process that converts metal into its oxide, hydroxide or sulphide to lose its metallic characteristics.

Rust is chemically known as hydrated ferric oxide (it is formulated as Fe_2O_3.xH_2O). Rusting results in the formation of scaling reddish-brown hydrated ferric oxide on the surface of iron and iron-containing materials.

Corrosion types:

1. Dry corrosion or Chemical corrosion

2. Wet corrosion or Electrochemical corrosion

Methods of corrosion prevention:

Alloying, surface coating, galvanization, electroplating, anodizing and cathodic protection.

Pamban Bridge is a railway bridge that connects the town of Rameshwaram on Pamban Island to mainland India. We can control the corrosion of the historical Pamban bridge by a periodical protective coating.