PDF chapter test TRY NOW

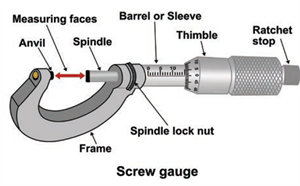

A screw gauge is a measuring instrument that can measure the dimensions up to 1/100th of a millimetre or 0.01 mm. With the screw gauge, it is possible to measure the diameter of a thin wire and the thickness of thin metallic plates.

Construction of Screw gauge

Description of screw gauge:

The screw gauge contains a U shaped metal frame. A hollow cylinder is connected to one end of the frame. Grooves are cut on the inside surface of the cylinder through which a screw passes (shown in the above figure).

- On the cylinder parallel to the axis of the screw, there is a scale which is graded in millimetres. It is called Pitch Scale (PS).

- One end of the screw is connected to a sleeve. The head of the sleeve (Thimble) is split into 100 divisions called the Head scale.

- The end of the screw has a plane surface which is known as Spindle.

- A stud called Anvil is attached to the other end of the frame, just opposite to the tip of the screw. The screw head is fitted with a ratchet arrangement (safety device) to prevent the user from exerting undue pressure.

Uses of Screw gauge:

The important uses of screw gauge are as follows,

- It is used to measure the diameter of circular objects, mostly wires with an accuracy of 0.001cm.

- It can be used to measure the diameter of a wire.

- It can also be used to measure the thickness of a paper.